What is Lean project management? Definition, methodology and best practices

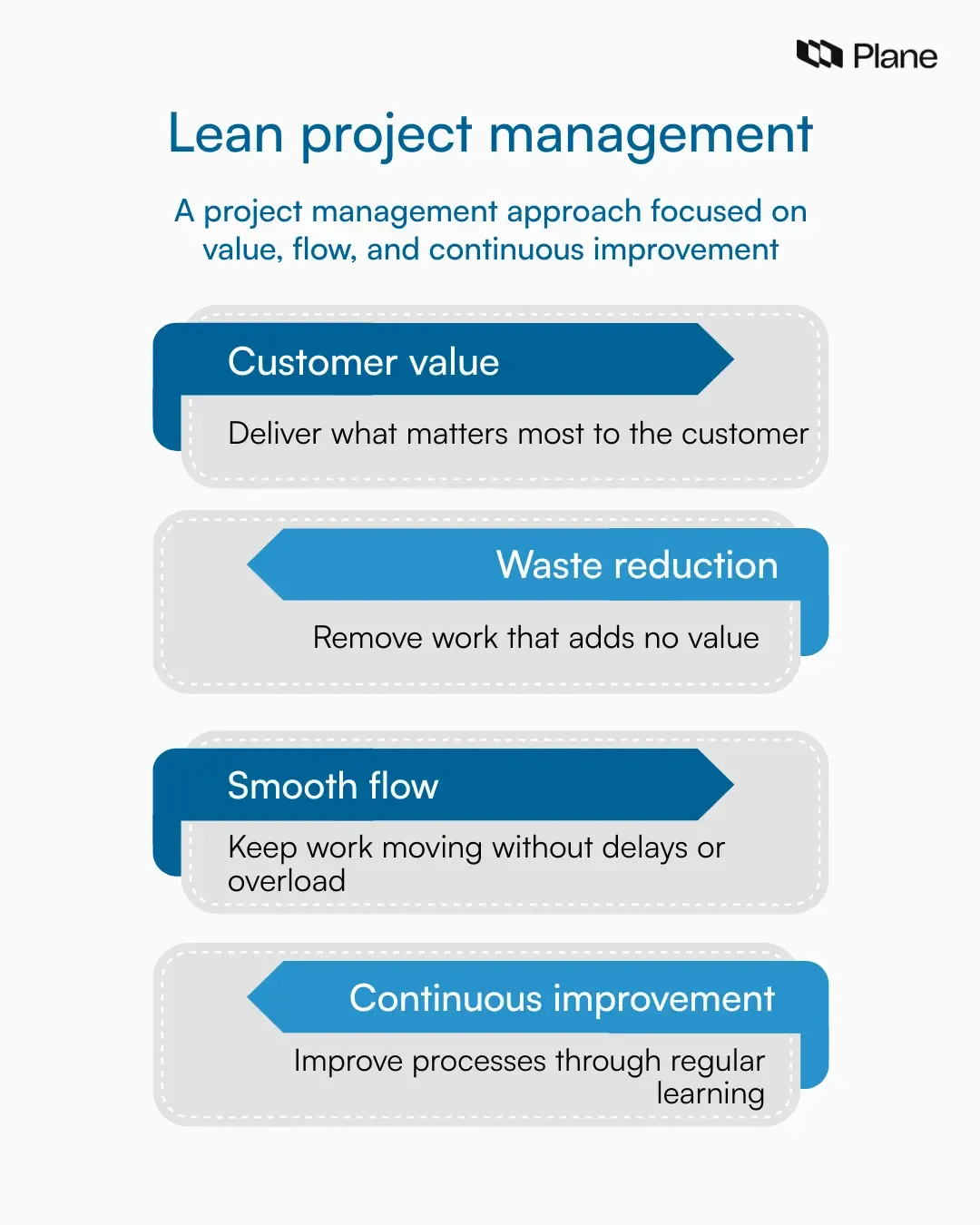

Lean project management is defined as an approach that emphasizes maximizing value while minimizing waste in project processes.

Lean project management is defined as an approach that emphasizes maximizing value while minimizing waste in project processes.

Introduction

Lean project management is about doing the right work, at the right time, with the least possible friction. It helps teams cut through complexity, reduce waste, and build systems that enable work to flow smoothly from idea to delivery.

This guide covers everything you need to understand lean project management from the ground up. We walk through the lean methodology, explain the five principles of lean project management, outline the lean project management process step by step, and highlight practical tools and techniques teams use to stay focused and efficient. You will also see when to use lean project management and how it creates real, measurable benefits in project execution.

What is Lean project management?

Lean project management is defined as an approach that emphasizes maximizing value while minimizing waste in project processes.

Originating from Lean manufacturing principles, particularly from Toyota's production system, Lean project management focuses on delivering value to the customer efficiently by reducing non-value-adding activities, streamlining workflows, and continuously improving processes. The core objective is to eliminate any form of waste, such as excess time, resources, or efforts that don’t directly contribute to the project’s goals or customer satisfaction.

A key principle in Lean project management is identifying and eliminating seven types of waste, commonly referred to as "muda." These include overproduction, waiting, unnecessary transportation, over-processing, excess inventory, unnecessary movement, and defects.

By focusing on these areas, project teams aim to streamline processes, ensuring that each step adds value. Lean encourages teams to regularly review their workflows and processes, making incremental improvements to enhance efficiency, reduce costs, and deliver faster results without sacrificing quality.

Lean project management also emphasizes a strong customer focus, where the needs and preferences of the customer drive the project's direction. Instead of simply following a predefined plan, Lean teams continuously gather customer feedback to refine their approach. This iterative process ensures that the final product or service aligns closely with customer expectations, reducing the likelihood of wasteful efforts or rework.

Additionally, Lean fosters a collaborative work environment, encouraging cross-functional teamwork and empowering employees at all levels to contribute to process improvement.

An example of Lean project management can be seen in software development projects. Suppose a development team is tasked with creating a new mobile application. Instead of spending extensive time upfront in detailed planning and documentation, the team focuses on quickly delivering a minimum viable product (MVP) to gather feedback from users. By continuously collecting input from users, the team can adjust the application in short iterations, making improvements that directly address customer needs. Throughout the process, the team actively identifies areas of waste, such as unnecessary features or redundant testing steps, and eliminates them, ensuring the project moves forward efficiently and cost-effectively.

Related: What is Kanban project management?

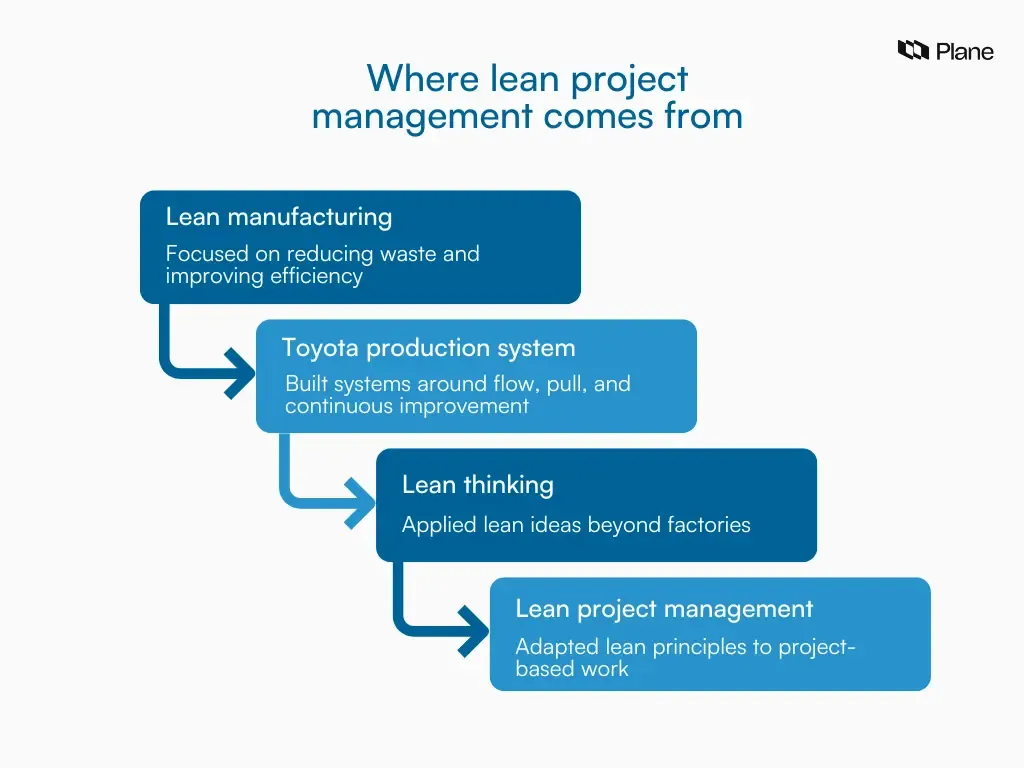

Where does lean project management come from?

Lean project management did not start in project management. It comes from lean manufacturing, where the focus was on improving how work flows through a system and removing anything that slows it down or adds no value. Over time, these ideas were adapted for knowledge work and projects, where delays, rework, and handoffs create similar problems.

1. Roots in lean manufacturing and the Toyota production system

Lean thinking originated in the Toyota production system, where teams focused on producing only what was needed, when it was needed, and with as little waste as possible. Instead of maximizing output, the goal was to maximize value while keeping processes simple and efficient.

Toyota achieved this by studying how work moved through the system, identifying delays and inefficiencies, and improving the process step by step. These ideas later became known as lean manufacturing.

2. How lean moved from factories to projects

As organizations began applying lean ideas outside manufacturing, they realized the same problems existed in project work. Tasks waited in queues, teams worked on too many things at once, and effort went into work that never reached the customer.

Lean project management adapts manufacturing principles like flow, pull, and continuous improvement to project environments. Instead of physical products, teams manage tasks, information, and decisions, aiming to move work smoothly from start to finish with minimal waste.

3. Lean as a mindset, not just a process

Lean project management is not a fixed framework or checklist. It is a way of thinking about how work should move through a system. The focus stays on customer value, improving flow, and learning from real outcomes.

Rather than following rigid plans, teams observe how work actually happens and make small, ongoing improvements. This mindset helps teams build project systems that stay efficient, adaptable, and focused on results.

Lean waste: 3M and the 7 wastes

Lean project management focuses on improving how work flows by reducing waste that slows teams down or adds no customer value. In lean thinking, waste shows up not only as extra work, but also as overload and uneven workflows.

1. The 3M view of waste

Lean groups waste into three broad patterns:

- Muda: work that does not create customer value

- Muri: overburden on people or systems

- Mura: uneven or inconsistent flow of work

Together, these help teams understand why projects become inefficient.

2. The 7 wastes in project management

The 7 wastes describe common inefficiencies teams see in daily project work:

- Overproduction

- Waiting

- Transportation

- Over-processing

- Inventory

- Motion

- Defects

Recognizing these wastes helps teams simplify workflows and improve delivery without adding more process.

Key components of Lean project management methodology

Lean project management methodology is built around several key components that aim to maximize value while minimizing waste in project execution. These components are essential for fostering efficiency, continuous improvement, and a strong focus on customer value. Here are the key components of Lean project management:

1. Value definition:

At the heart of Lean project management is the focus on delivering value to the customer. The first step is identifying what constitutes value from the customer’s perspective. This involves understanding the needs, preferences, and expectations of the customer and aligning the project’s goals accordingly. Only activities that contribute directly to delivering this value are prioritized, while non-value-adding activities are minimized or eliminated.

2. Waste identification and elimination (Muda):

Lean project management focuses on identifying and eliminating the seven types of waste ("muda"). By actively looking for these wasteful activities, teams can streamline processes, reduce costs, and improve overall efficiency. The continuous removal of waste ensures that resources are allocated effectively and project timelines are optimized.

3. Continuous improvement (Kaizen):

Lean places a strong emphasis on continuous improvement, or Kaizen, which involves making incremental changes to processes to increase efficiency and productivity. This requires teams to regularly evaluate their workflows and identify areas for improvement. By constantly refining processes, Lean teams can adapt to changes, eliminate inefficiencies, and improve their ability to deliver value. Everyone in the team is encouraged to contribute to this ongoing improvement process, making it a collaborative effort.

4. Pull-based workflow:

A key component of Lean is the use of a pull-based system, where work is initiated only when there is a demand for it, rather than pushing tasks based on a pre-determined schedule. This minimizes overproduction and ensures that the team focuses on tasks that are immediately needed to deliver value. By using tools like Kanban boards, teams can visualize workflows and manage work-in-progress (WIP), ensuring that tasks are completed in a timely and efficient manner without creating bottlenecks.

5. Just-In-Time (JIT) production:

Just-in-time production is another critical component of Lean, which involves producing or delivering products and services only as needed, without maintaining excess inventory or resources. This approach ensures that resources are used efficiently and that no unnecessary costs are incurred due to overproduction or storing excess materials. JIT ensures a leaner, more cost-effective project process, reducing lead times and improving the ability to respond to customer demands.

6. Respect for people:

Lean project management emphasizes respect for all team members and stakeholders. It encourages collaboration, empowerment, and open communication across all levels of the organization. By involving everyone in the process, Lean creates an environment where employees feel valued and are motivated to contribute ideas for continuous improvement. Respect for people also involves providing the necessary support and training to enable employees to succeed in their roles.

7. Flow optimization:

Ensuring smooth and efficient workflow is crucial in Lean project management. This means identifying and addressing any disruptions, bottlenecks, or delays that hinder progress. Optimizing flow involves synchronizing the project’s tasks so that work moves efficiently from one stage to the next without unnecessary waiting or overburdening any team members. By maintaining an optimal flow, projects can be completed faster and more efficiently, leading to better outcomes and customer satisfaction.

The 5 principles of lean project management

Lean project management is built around five core principles that guide how teams think about work, value, and improvement. These principles describe the intent behind lean, not the steps or tools used to apply it.

- Identify value

Focus on what truly matters to the customer. - Map the value stream

Understand how work moves from start to finish. - Create flow

Aim for smooth progress without unnecessary delays. - Establish pull

Let demand guide when work begins. - Pursue continuous improvement

Keep refining processes through regular learning.

These principles provide a shared mental model for lean project management. How teams apply them in practice is covered in the sections that follow.

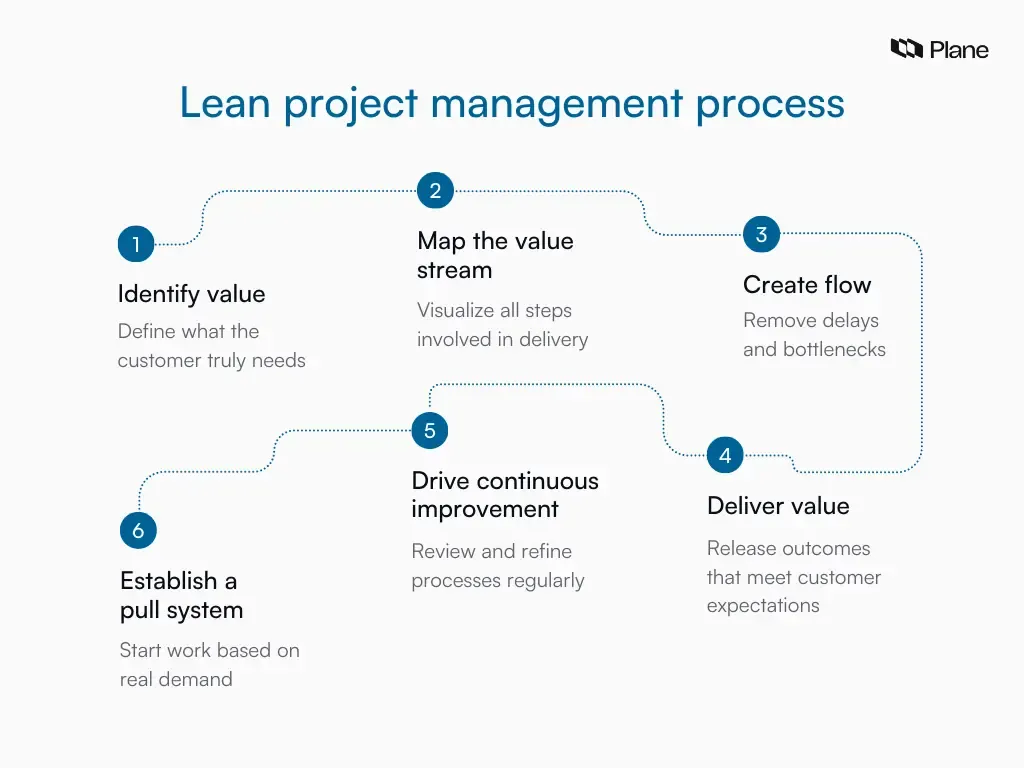

Lean project management process: Key steps

The Lean project management process is structured to focus on delivering value to the customer while minimizing waste and inefficiencies. It consists of several key steps that guide teams through the project lifecycle, emphasizing continuous improvement and the elimination of non-value-adding activities. Here are the key steps in the Lean project management process.

1. Identify value

The first step in Lean project management is to clearly define what constitutes value from the customer's perspective. This involves engaging with stakeholders and customers to understand their needs, goals, and expectations. The value should be measured in terms of what the customer is willing to pay for, and the project team must align its efforts toward delivering this value. Only activities that contribute directly to delivering the identified value are prioritized, and unnecessary activities are minimized or eliminated.

2. Map the value stream

Once the value has been defined, the next step is to map out the value stream, which is the entire flow of activities required to deliver the product or service. This process includes identifying all the steps involved in transforming inputs (such as raw materials, information, or labor) into the final deliverable. During this step, the project team should focus on identifying which activities add value and which ones contribute to waste (non-value-adding activities). This visual map helps teams understand how work flows through the system and highlights areas where improvements can be made to eliminate waste and inefficiencies.

3. Create flow

After mapping the value stream, the next step is to ensure a smooth flow of work throughout the project. This involves optimizing the process so that work moves efficiently from one step to the next without interruptions, delays, or bottlenecks. Teams should eliminate any waste identified in the previous step and ensure that each task or phase transitions seamlessly. The goal is to streamline operations, reduce wait times, and prevent overburdening any part of the process, ensuring that the project progresses as smoothly and quickly as possible.

4. Establish a pull system

In Lean project management, a pull-based workflow is preferred over a push-based system. In a pull system, work is initiated only when there is actual demand for it, meaning tasks are "pulled" through the system based on customer needs or requirements rather than being "pushed" through based on a pre-determined schedule. This approach minimizes overproduction, reduces waste, and ensures that resources are allocated only to activities that directly contribute to the final deliverable. Tools like Kanban boards are often used to visualize the workflow and control the flow of work, limiting the amount of work-in-progress (WIP) and avoiding overloading the team.

5. Pursue continuous improvement (Kaizen)

Lean project management is rooted in the principle of continuous improvement, or **Kaizen**. Throughout the project lifecycle, teams should regularly evaluate their processes and look for ways to improve efficiency, reduce waste, and increase value. Continuous improvement is a team-wide effort, and every team member is encouraged to contribute ideas for process enhancements. Regular reviews, feedback loops, and retrospectives help identify areas for improvement and ensure that the team is consistently working toward optimizing the process. This iterative approach allows Lean teams to adapt quickly and evolve their workflows based on real-time feedback and changing circumstances.

6. Deliver value

The final step is delivering value to the customer. By focusing on the steps mentioned above—defining value, mapping the value stream, creating flow, and using a pull system—Lean project management ensures that the product or service delivered meets the customer's needs with minimal waste and delays. Continuous improvement efforts throughout the project ensure that the process is constantly evolving to better meet the customer's expectations, ensuring high-quality deliverables. Customer feedback is also crucial in this step, as it informs future improvements and adjustments for ongoing or upcoming projects.

Related: What is Scrum project management?

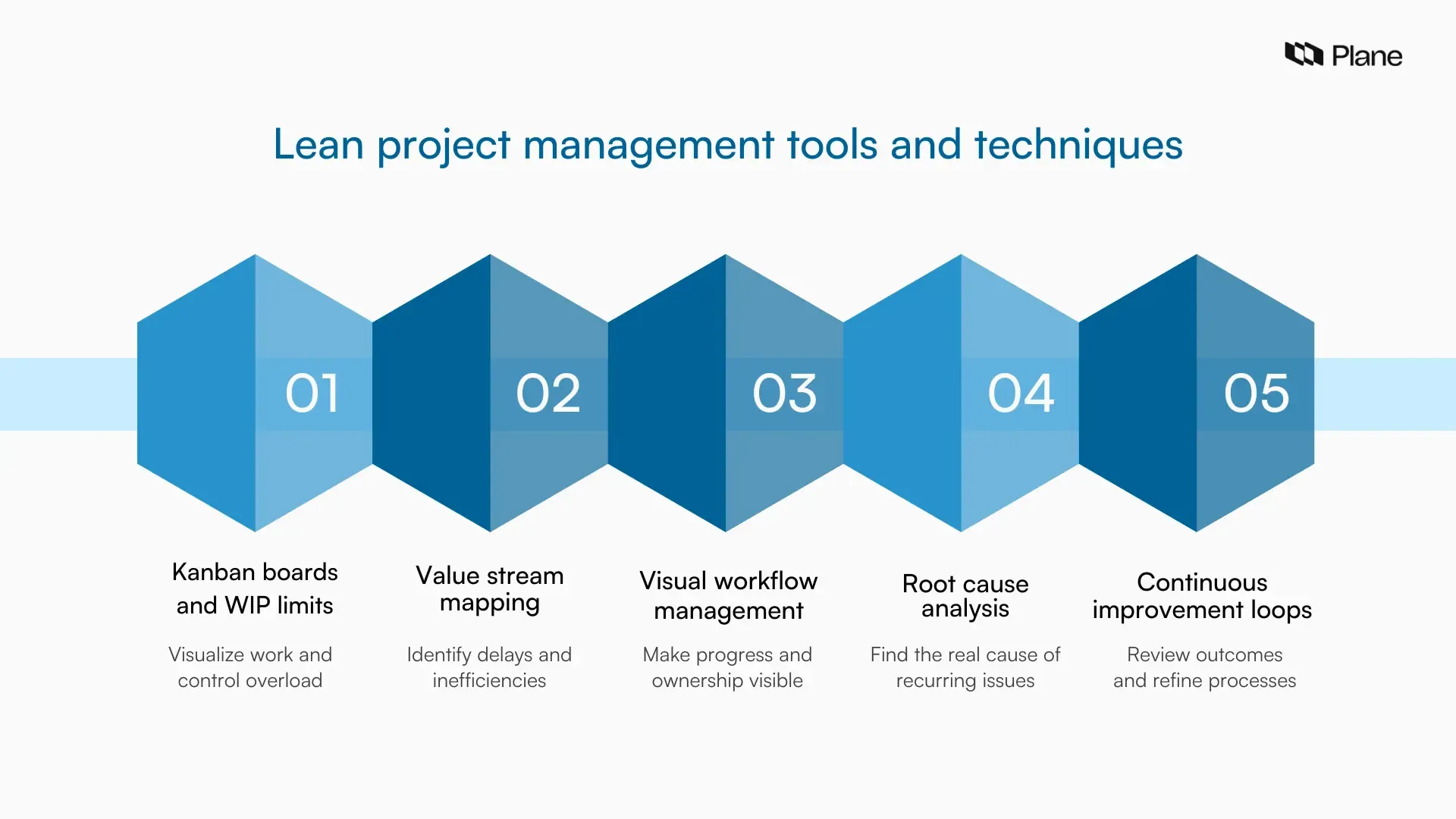

Lean project management tools and techniques

Lean project management relies on simple tools that help teams see work clearly, reduce waste, and improve how tasks move through a project. These tools support lean thinking without adding extra process or complexity.

1. Kanban boards and WIP limits

Kanban boards help teams visualize work as it moves through different stages. Work-in-progress limits reduce overload by controlling how many tasks are active at once, thereby improving focus and flow.

2. Value stream mapping

Value stream mapping shows the full path work follows from request to delivery. It helps teams spot delays, handoffs, and steps that add little value.

3. Visual workflow management

Visual workflows make project status visible to everyone. Clear columns, status labels, and ownership reduce confusion and speed up decision-making.

4. Root cause analysis (5 whys)

The 5 whys technique helps teams identify the root cause of recurring issues. By asking “why” multiple times, teams move beyond symptoms and fix problems at their source.

5. Continuous improvement loops

Regular reviews and feedback loops allow teams to learn from outcomes and adjust how they do their work. Small, consistent improvements help keep projects efficient over time.

Importance of Lean methodology for project management

The Lean methodology is highly important in project management because it provides a framework that focuses on efficiency, value, and continuous improvement. By emphasizing the elimination of waste, Lean helps organizations and project teams achieve better outcomes with fewer resources, enhancing both productivity and customer satisfaction. Below are several key reasons why Lean methodology is vital for project management:

1. Maximizing value while minimizing waste

At the core of Lean methodology is the concept of delivering maximum value to the customer while minimizing waste. In project management, waste can take many forms—such as inefficient processes, overproduction, waiting times, and unnecessary complexity. By systematically identifying and eliminating these wastes, Lean helps teams streamline their workflows, reduce costs, and focus only on activities that add value. This not only leads to more efficient project execution but also ensures that resources are used effectively, improving the project's bottom line.

2. Enhanced efficiency and productivity

Lean's emphasis on optimizing processes and removing bottlenecks improves the overall efficiency and productivity of project teams. By establishing smooth workflows, reducing waiting times, and minimizing redundant tasks, Lean enables teams to complete projects faster and with fewer resources. Tools such as Kanban boards help visualize the workflow and manage tasks in real-time, ensuring that work is balanced, and that team members aren’t overloaded. This approach helps keep the project on track and allows for faster delivery of results, which is particularly valuable in industries where time-to-market is critical.

3. Continuous improvement (Kaizen)

One of the most important aspects of Lean methodology is its focus on continuous improvement, or **Kaizen**. In project management, this means that teams are encouraged to regularly assess their processes and seek ways to improve efficiency, quality, and outcomes. The pursuit of small, incremental improvements can lead to significant gains over time. This mindset helps create a culture of constant learning and adaptability, ensuring that the project team is always evolving and improving. Continuous improvement helps teams respond to changing requirements or unexpected challenges, making them more resilient and agile over the course of the project.

4. Customer-centric focus

Lean methodology prioritizes customer satisfaction by ensuring that every activity in the project is aligned with delivering value to the customer. Projects managed under Lean principles are guided by customer needs, which means that features, processes, or deliverables that do not contribute to customer value are minimized or eliminated. By continuously involving customers or stakeholders in the process and gathering feedback, Lean helps ensure that the final product or service meets or exceeds customer expectations. This strong focus on value creation builds better customer relationships and improves project outcomes.

5. Improved collaboration and teamwork

Lean methodology encourages a collaborative working environment, where team members from different disciplines work together to optimize processes and solve problems. Lean teams often adopt cross-functional practices, ensuring that everyone contributes to the project's success. This teamwork is further reinforced by the concept of respect for people, which is a key principle of Lean. Empowering team members to take ownership of their work and contribute ideas for improvement fosters a sense of responsibility and engagement, leading to better project outcomes. Improved collaboration also leads to quicker problem resolution, as issues are identified and addressed collectively.

6. Better resource management

Lean methodology helps project managers better manage resources, including time, labor, and materials. By focusing on just-in-time (JIT) production, Lean reduces excess inventory and minimizes resource waste. Lean's pull-based approach ensures that work is initiated only when needed, preventing overproduction and overcommitment of resources. This method of resource management ensures that projects are completed with optimal resource usage, leading to cost savings and reducing the risk of project delays caused by inefficient resource allocation.

7. Risk reduction

By regularly reviewing workflows, identifying inefficiencies, and maintaining a customer-focused approach, Lean project management helps reduce risks associated with waste, cost overruns, and project delays. Continuous improvement efforts ensure that potential problems are identified and addressed early in the project, preventing them from escalating into bigger issues. This proactive risk management is a significant advantage of Lean, as it allows project managers to stay ahead of challenges and maintain control over the project’s scope, schedule, and budget.

Related: What is project life cycle?

Best Practices for using Lean project management in 2024

To effectively implement Lean project management, there are several best practices that help maximize the benefits of the methodology, including improving efficiency, eliminating waste, and delivering greater value to the customer. These practices ensure that Lean principles are applied in a structured and impactful way. Here are the best practices for using Lean project management:

1. Clearly define customer value

One of the foundational principles of Lean project management is focusing on customer value. To do this effectively, you need to start by identifying what the customer truly needs and values. Engage with stakeholders early to understand their requirements, expectations, and objectives. This will help ensure that every activity in the project contributes to delivering value, while non-value-adding activities are minimized or eliminated. Maintaining a strong, continuous focus on customer satisfaction throughout the project helps in delivering results that meet or exceed their expectations.

2. Map and visualize the value stream

Mapping the value stream involves laying out all the steps, from the beginning of the project to final delivery, to understand the flow of work and identify any inefficiencies. By using tools like value stream mapping or process flow diagrams, you can visualize the sequence of tasks and determine which ones add value and which ones generate waste. This helps teams identify bottlenecks, delays, or redundant processes that can be eliminated or improved. Tools like Kanban boards are also useful in visualizing workflows, allowing teams to track progress and manage tasks in real-time.

3. Focus on continuous improvement (Kaizen)

Lean project management thrives on the principle of continuous improvement, also known as Kaizen. Establish a culture of ongoing evaluation where the team regularly reviews processes and looks for ways to optimize them. Encourage everyone on the team, regardless of role, to contribute ideas for improving efficiency, reducing waste, and delivering higher quality. Conduct regular retrospectives after completing significant project phases or tasks to identify what went well and where improvements can be made. Small, incremental improvements can lead to significant efficiency gains over time.

4. Eliminate waste (Muda)

Teams should continuously identify and remove non-value-adding activities that contribute to inefficiency. Waste can take various forms, such as excess inventory, unnecessary motion, overproduction, waiting, or rework due to defects. It’s crucial to focus on each of the seven wastes defined in Lean (overproduction, waiting, transportation, over-processing, inventory, motion, and defects) and develop strategies to minimize them. By reducing waste, teams can focus their energy and resources on activities that directly contribute to the project’s goals.

5. Establish a pull-based system

Lean project management advocates for a pull-based system rather than a push-based one. In a pull-based system, work is only initiated when there is actual demand for it, preventing overproduction and unnecessary use of resources. This method ensures that project tasks are driven by customer needs or internal demands, not by arbitrary schedules. Kanban boards or similar visual tools can help manage this pull system by clearly indicating what work needs to be done and limiting the amount of work-in-progress (WIP) to avoid overburdening the team.

6. Create and maintain smooth workflows

Ensuring smooth, uninterrupted workflows is essential for keeping the project moving efficiently. This involves identifying and addressing any bottlenecks, delays, or work stoppages that can slow down progress. Lean methodology emphasizes flow optimization, where each phase or task transitions smoothly to the next without unnecessary waiting times or excess handoffs. Regularly review the workflow to make adjustments, ensuring that processes remain streamlined and effective throughout the project lifecycle.

7. Empower and involve the team

Lean project management encourages collaboration and empowers every team member to contribute to the project’s success. Teams should be cross-functional, with open lines of communication across different roles and disciplines. This creates a culture of accountability and shared ownership, where each person feels responsible for the outcome of the project. Encouraging team members to take initiative and suggest improvements can lead to innovative solutions and process efficiencies. In addition, respect for people is a key Lean principle, and creating a supportive, collaborative work environment is vital for success.

8. Focus on Just-In-Time (JIT) delivery

Lean project management incorporates **Just-In-Time (JIT)** production, which means delivering the right amount of work at the right time, with minimal excess inventory or resources. This ensures that teams are only working on tasks that are immediately necessary, which prevents overproduction and reduces waste. JIT ensures that teams focus their efforts on what is needed to deliver value in the short term, helping to maintain a leaner, more efficient workflow. By aligning tasks with actual demand, JIT also helps in reducing unnecessary costs and project delays.

9. Measure performance with metrics

Tracking and measuring performance is crucial in Lean project management to ensure that the project is progressing efficiently and that improvements are making a difference. Use key performance indicators (KPIs) such as cycle time, lead time, throughput, and work-in-progress limits to assess the team's efficiency and identify areas for improvement. Data-driven decision-making enables teams to focus on areas where improvements can have the most significant impact and helps ensure that the project stays on track.

10. Build strong customer feedback loops

Lean project management relies on constant feedback from the customer or stakeholders to ensure that the project stays aligned with their needs. Establish feedback loops that allow for continuous input from the customer throughout the project lifecycle. Whether through regular reviews, demonstrations, or prototype testing, feedback helps the team adapt quickly and ensures that the final deliverable meets customer expectations. Early and frequent feedback minimizes the risk of producing deliverables that do not meet the intended value.

Conclusion

Lean project management offers teams a clear way to improve how work moves from idea to delivery. By focusing on value, reducing waste, and continuously improving workflows, the lean methodology helps teams create predictable outcomes without adding complexity.

In this guide, we covered what lean project management is, where it comes from, the principles that shape it, the tools that support it, and the best practices teams use to apply it in real projects. When used in the right context, lean project management creates focus, improves flow, and helps teams deliver work that truly matters to customers.

Frequently asked questions

Q1. What does lean mean in project management?

Lean in project management means focusing on delivering customer value while reducing waste in how work is planned and executed. It helps teams improve flow, limit unnecessary work, and continuously improve processes so projects move faster and more predictably.

Q2. What are the 5 principles of lean project management?

The five principles of lean project management are:

- Identify value

- Map the value stream

- Create flow

- Establish pull

- Pursue continuous improvement

These principles guide how teams think about work and decision-making.

Q3. What is lean vs agile?

Lean focuses on optimizing flow and reducing waste across the entire project system, while Agile focuses on iterative delivery and adapting to change through short cycles. Lean improves how work moves, and Agile improves how teams respond to feedback. Many teams use both together.

Q4. What are the 5 C’s of lean?

The 5 C’s of lean are:

- Clear out

- Configure

- Clean and check

- Conform

- Custom and practice

They are used to organize workspaces and processes for efficiency and consistency.

Q5. What are the 7 lean principles?

The commonly referenced 7 lean principles include:

- Eliminate waste

- Build quality in

- Create knowledge

- Defer commitment

- Deliver fast

- Respect people

- Optimize the whole

These principles expand on lean thinking and are often used alongside the core five principles.

Recommended for you